Introduction

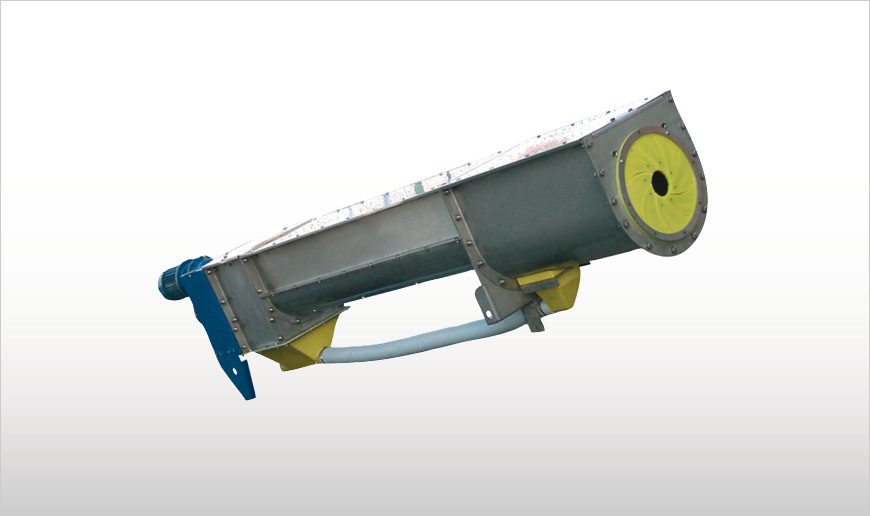

WASTECOM CPS is a de-watering screw compactor for screened solids in civil and industrial waste water treatment plants.

Up to 40% reduction of screenings volume

Fully enclosed, pollution-free, odour-free

Particularly maintenance-friendly modular design

Technical Specs

Description

WASTECOM CPS Screw Compactors consist of a conveyor trough manufactured from stainless steel, a shaftless extra heavy-duty spiral manufactured from carbon steel, a compacting and de-watering discharge module, a return duct for pressed out water, and a drive unit suitable for the application.

Function

Three functions in one unit: conveying, de-watering and compacting.

Designed for intermittent operation, WASTECOM CPS Screw Compactors can be employed in various de-watering applications and in combination with different type solids-liquid separators or conveyors. Usually applied for compacting various solids from different processes (municipal/industrial waste water treatment, food processing, slaughterhouses, rock wool industries, plastics recycling processes, etc.).

Features

- Fabricated structure completely manufactured from 304L / 316L SS

- Highly wear-resistant extra heavy-duty mild steel or 304/316 SS spiral

- Trough liner manufactured from HDPE high-density, low-friction polymer

- No outlet and intermediate bearing assemblies

- No mechanical components in contact with material handled

Benefits

- Two functions: conveying and compacting

- Up to 40% reduction of screenings volume

- Particularly maintenance-friendly modular design

- No machine locking even with fibrous materials

- Fully enclosed, pollution-free, odour-free

- Low noise level

- Low energy consumption

Options

- Compacting screen basket mesh

- Trough liner

- Drive guard

- Alternative voltage/frequency

- Alternative degree of motor protection

- Control panel

- Compaction washing system

Accessories

- Outlet verticaliser

- Endless tube

- Bag fastening system

- Rectangular inlet

- Adjustable support stands

- Support bracket

- Plug retention SINT diaphragm with different resistance levels